The fuel is loaded into the chamber and the door closed. The fuel is then ignited from the rear (or, if the previous burn still has embers left it should self-

The Fans self-

When the boiler reaches temperature the shunt pump starts, heat is then transferred into the buffer tank (also called accumulator tank) from the boiler. The size of this tank will depend on the size of the boiler and demands of the user, it acts like a battery and as the tank is super insulated the heat can be held for days at a time (often losing just one degree per day). The bigger the tank, the more heat it can hold meaning when heat demand is less, the process of loading the boiler could be reduced to perhaps once or twice a week.

As with all batch burners, the system is designed to burn the bale at the optimum temperature meaning a bale can burn completely in just 4-

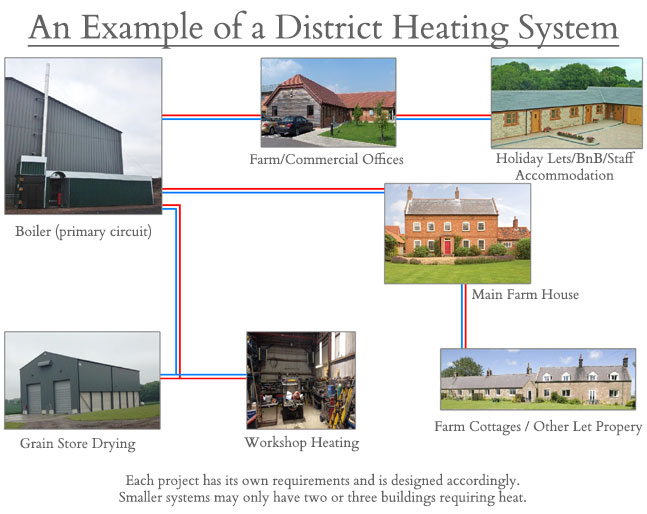

The heat in the tank can then be distributed around the secondary system via pumps and pipe work. The secondary side is very much site specific, each is designed by us according to the heat requirements of the client.

Examples of heat use which we can supply include:

- All domestic property of any size

- Workshops and commercial buildings

- Offices, work rooms, (Farm) Shops.

- Grain Driers,

- Leisure centres, Nurseries (child or plant), enclosed swimming pools

- Potato / vegetable handling facilities

- Poultry sheds / stock rearing

- Glass houses and horticulture.

The Secondary system can be designed to be as simple or as complex as required. Have a look at this generic example of how flexible the systems can be here:

Generally heat is distributed to residential / office units using a ‘wet system’-

For workshops or large commercial spaces, blow heaters are usually used. We also supply an excellent range which makes light work of heating any sized building. These are quick and cheap to fit and are very responsive to heat needs, they come with variable speed setting so they can be turned down if welding / spray painting foe example.

For Grain drying, depending on the system we have two options. For on floor drying, large Heat Exchange units (think car radiators but 2m2 x 2 m2 plus) are fitted into the opening of the Fan House so when the fans are turned on, the pumps start which warm up, and more importantly dry the air as it passes into the fans. Personal tests on two systems have shown that when the Relative Humidity is 90%+ outside (i.e. raining) the RH of the air can be brought down to 30% (potentially too dry!) with ease. Temperature gains can also be 20 – 40 degrees C or more, depending on what is required. Existing systems are really easy to connect into keeping things automated so you can focus on the combining and drilling. Grain drying alone can pay for the complete biomass install in a matter of a few years if the demand is there. It’s a great option to have in conjunction with other property but is by no means essential to make it a viable business investment.

For continuous flow dryers it is possible to fit a bank of fan assisted heat exchange units to pre heat the air which substantially reduces traditional fuel use. We bring in specialist engineers for these projects as required to ensure you get the best from the system.

The pumps and fans needed to run both the primary and secondary systems need electricity. All though the fans only run for a few hours at a time, the pumps often run for much longer. The cost of running these is only a few £100 pounds per annum, which compared to the income from RHI are a very small and a largely insignificant figure. If solar panels have been installed to buildings then this system works particularly well as generally, the pumps are mostly on during the day which is usually when the sun is out.

If heat pipes are being installed it’s a good idea to look at other service upgrades to the farm at the same time and make the most of the trenches.

It is possible to have an internet based control panel which can monitor the entire system and send email or text alerts if problems occur. Not only does this notify the maintenance team instantly but they will also be able to identify which component has gone down, saving them from walking from building to building trying to diagnose the problem (very helpful on large schemes with multiple properties!). Further, this system can automatically read all the heat meters to each property for billing purposes meaning invoices are raised from the office desk rather than walking around to each property with notepad. Fuel use can also be compiled allowing you to predict future fuel needs as well as confirming the quality of your current supply for the straw burner.

Back up heating systems can also be fitted with ease, either existing boilers which in the event of a break down can be turned back on (with our systems often there is enough stored heat for a few days before it’s cold enough for tenants to even notice) or, in the case of some clients, a dedicated

boiler and back up generator. This means, in the event of a power cut, heat can still be produced and each house heated, an excellent feature for those with multiple rented units.

Wherever possible we try to design the system so all pumps are interchangeable. This can cut down on both initial install costs and in the event that a pump goes down, the pump from another zone can be swapped in a matter of minutes to ensure continuous supply.

StrawBurners.co.uk is a trading name of PedigreeProperties.co.uk, proudly offering the same ethics and approach to clients that has kept Pedigree Properties at the top of their field for many years.

Nick Nixey -

The Farm House, Lobb Farm, Tetsworth

Thame, Oxford, OX9 7BE

Home The Boilers How They Work RHI Facts and Figures Case Studies About us Contact Us

StrawBurners.co.uk is a trading name of PedigreeProperties.co.uk © 2015 -